Product Description

The discharge rubber hoses are suitable for dredging sand & slurry. It is normally installed between the HDPE dredging pipes to ensure the whole pipelines more flexible. BOYU Pipe could supply dredging rubber hoses ranging from 100mm inner diameter to 1200mm inner diameter with various length and pressure ratings.

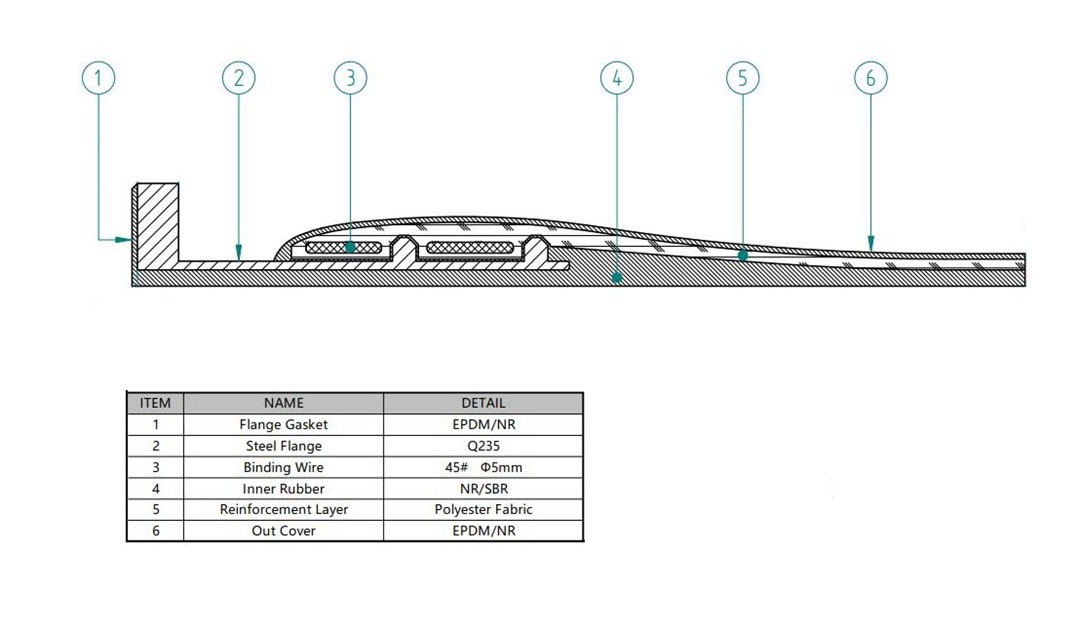

A discharge rubber hose with steel nipple is composed of lining, reinforing piles, outer cover and hose fittings at both ends. The main materials of its lining are NR and SBR, which have excellent wear resistance and aging resistance. The main material of its outer cover is NR, with excellent weather resistance, corrosion resistance and other protective properties. Its reinforcing piles are composed of high-strength fiber cords. The materials of its fittings include carbon steel, high-quality carbon steel, etc., and their grades are Q235, Q345 and Q355.

Technical Parameters

Nominal Bore Size | 200mm, 300mm, 350mm, 400mm, 450mm, 500mm, 600mm, 700mm, 800mm, 900mm, 1000mm, 1100mm, 1200mm |

Hose Length | 1m~ 11.8m (tolerance ± 2%) |

Working Pressure | 0.8 Mpa ~ 3.5 Mpa |

* Customized specifications are also available. | |

Discharge Rubber Hose Technical Properties

Dredging Rubber Hose Technical Properties | ||

Items | Index | Notes |

Working Pressure (Mpa) | ≥0.80 | 1-The technical data shows here just follows the standard of HG-T2185-9. 2-The strength layer is 200D/3 cord fabric and the pulling force is 380N for each single root. |

Test Pressure (Mpa) | ≥1.2 | |

Burst Pressure(Mpa) | ≥2.4 | |

Conveying Medium | Muddy, Water | |

Tensile Strength(Mpa) | ≥11.80MPa | |

Elongation(%) | ≥400 | |

Ozone Testing | No Cracking in 48 hours exposed in Ozone | |

Abrasion | ≤0.395cm3 | |

Ageing Resistance | Ageing Resistance | |

Shore Hardness A | 63±3 | |

Adhesion Strength Between Each Layer(KN/m) | ≥1.0 | |

Strength Layer | 4 layers of cord fabric | |

Dredging Rubber Hose Advantages

The discharge rubber hose is mainly used in the main conveying pipelines matching with dredgers in dredging projects. It is the most used hose in dredging pipelines. It can be used in various positions such as CSD(cutter suction dredger) stern, floating pipelines, underwater pipelines onshore pipelines, and the water-land transition of pipelines. Discharge rubber hoses are usually alternately connected with HDPE pipes or steel pipes to form a pipeline, they can improve the bending performance of the pipeline to the greatest extent, and is especially suitable for floating pipelines used in strong winds and big waves. In case that the pipeline needs to be bent to a large degree, or used in places with large height drop, two or more discharge rubber hose can be connected in series to adapt to such bending conditions. The discharge rubber hose main features as follows:

1. With excellent wear resisitance.

2. With good flexibility and moderate stiffness.

3. Can remain unobstructed when bent to certain degrees during use.

4. Can be designed to withstand various pressure ratings.

5. The built-in flange seals ensures good sealing performance between the flanges connected.

6. Easy to install, safe and reliable, suitable for a wide range of applications.