HDPE Dredging Pipe with non-toxic, odorless, good heat and cold resistance. The pipe is made by PE100 high density polyethylene materials. HDPE dredge pipes are widely used for dredging industries, dredger pipelines, sand pumping pipelines, etc.

HDPE Dredging pipe is high rigidity and toughness with high mechanical strength. It has ultra-high resistance, abrasion degree is 4-8 times of steel pipes, useful life can reach more than 5 years. It can withstand the impact of wind and waves on the sea, With good performance, high chemical stability, it can withstand various corrosive media (acid, alkali, salt, etc.) within a certain temperature and concentration range.

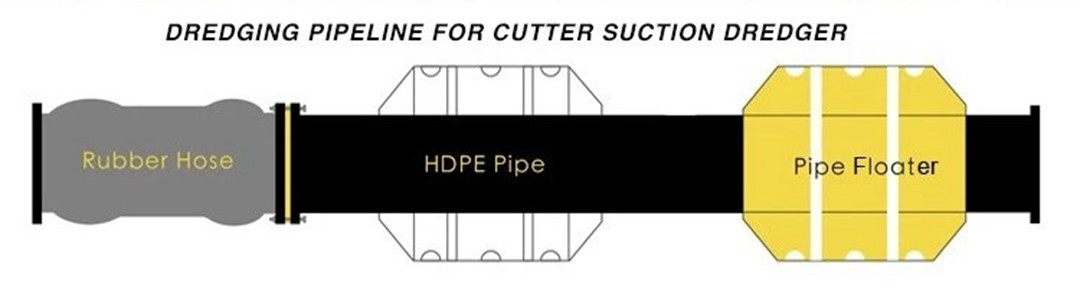

HDPE dredging pips are manufactured and welded from two HDPE flange adapters and two steel flanges where the two pipes can be easily joined together by flanges and covered with floats to keep them afloat.

HDPE Dredging Pipes are usually produce in 6 or12 meters lenghts. The pipe can be provided from OD110mm to OD1400mm. with various wall thickness as per different SDR & designed pressure rating, and custom-made steel backing rings are available.

HDPE Dredging Pipe Specifications

Dredge pipes are available for sale in SINCO. We provide the HDPE pipes from OD110mm to OD1400mm.

HDPE DREDGING PIPE SPECIFICATION TABLE | |||||

SDR | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

PN | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa |

OD (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) |

110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

140 | 6 | 7 | 8 | 10 | 13 |

160 | 7.5 | 8 | 10 | 12 | 15 |

180 | 7.5 | 9 | 11 | 13 | 17 |

200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

425 | 15 | 20 | 25 | 33 | 42 |

450 | 17.2 | 21.5 | 26.7 | 33.1 | 44.9 |

500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

710 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 |

800 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 |

850 | 32 | 40 | 50 | ||

900 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 |

950 | 36 | 45 | 56 | ||

1000 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 |

1200 | 45.9 | 57.2 | 70.6 | 88.2 | |

1400 | 53.5 | 66.7 | 82.4 | ||

Notes: 1. Pipe Length: 5.8meters or 11.5meters, could be customized. 2. Connection Type: Flange stub end on both pipe ends or inner steel ring lining bell end connection | |||||

HDPE Dredging Pipe Advantages

1 Corrosion resistance: high resistance to attach from various types of chemicals, no electrochemical corrosion, so HDPE dredge pipe can be used for sea water without worry about corrosion problem.

2 High toughness: fracture extension rate of HDPE dredging pipe, commonly more than 500%. As to the uneven settlement of the base, its adaptive ability is very strong, good aseismic performance.

3 Light weight: by comparing steel pipe, the HDPE dredge pipe is only 1/5 of steel pipe on the weight, less pipe floats be needed

4 Easy to assemble or dis-mountable: The HDPE dredge pipe welded with flanges can be assembled or disconnected very easily.

5 Excellent flexible and resistance to scratches ability: HDPE dredging pipe is more flexible than steel pipe, so less rubber hoses be required.

6 Good wear resistance, low wall friction coefficient, small flow resistance, excellent conveying ability: HDPE dredging pipe has a good toughness, smooth wall allows the pipeline has good wear resistance & high flow rate.

7 Low system cost, less maintenance costs, can dramatically reduce the cost for the project: HDPE dredge pipe is much lower price than steel pipe, at the same time more durable use when it is used for sea water.

8 Long service life: HDPE dredging pipe can service longer lifetime in sea water.

9 Recyclable and environment-friendly: HDPE material can be reused, complete with the concept of efficient environmental protection which our state advocates

HDPE Dredging Pipe Applications

1. HDPE Dredging Pipe could be used for transferring powder and coal ash in thermal power plant.

2. HDPE dredging pipe is suitable for delivering mine tailings and slurry, metallurgical mines in the mining industry.

3. HDPE dredging pipe can use for delivering pulverized coal and coal-water slurry of coal preparation plant in the coal industry.

4.Delivering mud and corrosive media with slag in the chemical industry.

5. Delivering crude oil and petroleum.

6. HDPE dredging pipe could be used for delivering sand\mud\slurry for dredger in dredging projects or sand suction projects, and also for seawater treatment projects.