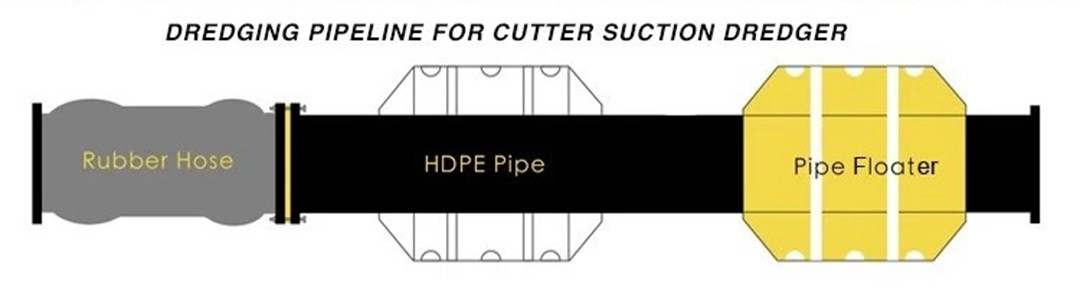

HDPE Dredging Pipe floaters/Floats are made of rotationally molded polyethylene with UV inhibitors to prevent degradation of the floats over time, which has been widely used for dredge work that used for discharging of sands, Sludge.,etc. The pipe floats can provide sufficient buoyancy to maintain the whole dredge pipeline floating above the water. BOYU HDPE Dredging pipe and floats are perfect solutions for dredging works, dewatering, pumping and other industrial projects.

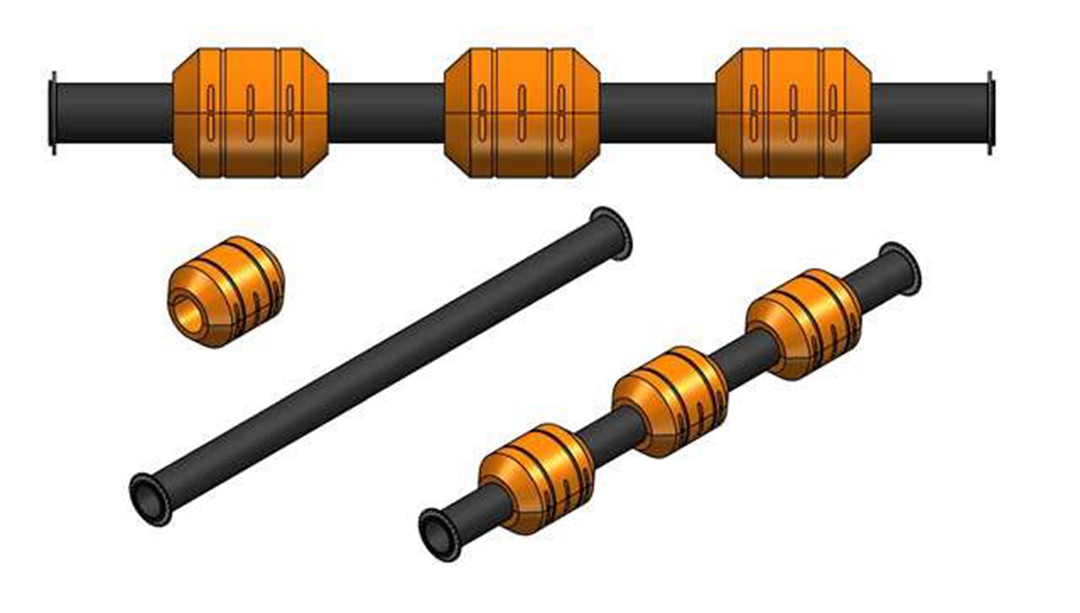

BOYU dredge pipe floater/floats are designed to be applied on HDPE dredge pipe & rubber pipes that be used for dredge works. Each dredge pipe floats are composed by two halves, fixed by bolts/nuts when place two halves on the pipe. The inside diameter of dredge floats shall be designed into a elliptical shape, so they can be fixed with pressure tightly, no slipping while assembled into the pipe.

Structure of Dredge pipe floats/floaters

Outer plastic shell: the pipe floats’ outer shell is made from LDPE, about 5-16mm thickness, which can withstand the impact of sea wave. The outer plastic shell is rotationally moulded in one-time, no second welding jointing, this assure the reliability of for normal use.

Inner filled material: Inside of dredge pipe floats is filled with PU foam. PU foam is very light weight & nonabsorbent material. This assure The dredge pipe floats/floaters can still work in case the outer shell is leaking.

The dredge pipe floater/floats are normally manufactured in orange or yellow color, which is a warning sign for the vessels passing by. Thanks to special design, the Dredge floater/floats can maximum absorb the energy from vessel collision, to protect the pipelines that they are supporting.

Specification

BOYU can supply various specifications of dredge pipe floats/floaters for choice. The customers can also find a right dredge pipe floats from us based on their dredge pipe.

HDPE Dredging Pipe floater/Floats Specification

Sinco can provide different specifications of Dredge Pipe Floats/Floaters for customers' options, covering most of all HDPE dredge pipe that we can provide. We understand that choosing the right size can be a challenge for customers who may not be familiar with the specifics of dredging projects. Our experienced team of professionals can guide customers through the selection process and help you make an informed decision.

Floating I.D (mm) | Floating OD(mm) | Length of Floating(mm) | Thickness(mm) |

150 | 300 | 500 | 6 |

220 | 600 | 700 | 6 |

250 | 700 | 900 | 6 |

280 | 700 | 1200 | 7 |

315 | 1000 | 1000 | 7 |

355 | 1100 | 1100 | 7 |

400 | 1200 | 1200 | 7 |

450 | 1200 | 1200 | 7 |

500 | 1300 | 1300 | 8 |

560 | 1400 | 1500 | 8 |

630 | 1450 | 1700 | 9 |

650 | 1500 | 1850 | 9 |

710 | 1500 | 1800 | 10 |

800 | 1800 | 2200 | 10 |

900 | 1800 | 2200 | 12 |

HDPE Dredging Pipe floater/Floats Technical Parameters

HDPE Dredging Pipe Floater/Pipe Floats Technical Prosperity | |||

Item | Floating Body Index | Item | Filler Index |

Tensile Strength | ≥12MPa | Water Absorption | 0.16-0.20g/100cm3 |

Break Elongation | ≥11% | Breaking Strength | 0.8-1.3MPa |

Impact Strength | ≥32KJ/m2 | Break Elongation | 0.4%-0.6% |

Bending Strength | ≥15.7MPa | Compression Strength | 0.1-0.24MPa |

Compression Strength | ≥0.31MPa | Heat Resistance | -60℃--+80℃ |

Shell Density | 0.918-0.922g/m3 | Filler Density | 45kg/m3 |

• HDPE dredging pipe floats/floaters are the first choice for dredging work due to their excellent properties.

• HDPE dredging pipe floats/floaters structure is impact and wave resistant, compact and reasonable, easy to install, and has excellent performance.

• Good toughness and high environmental stress cracking resistance (ESCR) ensure that dredge pipe floats are suitable for offshore and lake construction.

• Lightweight, strong wear resistance, easy installation and transportation, low cost of transportation and transformation.

• Corrosion and weather resistance, dredge pipe floater life is more than 3 times that of steel floats.

• Simple, fast, flexible assembly of diverse shapes.

• HDPE dredging pipe floaters/floats can be used in the sea for a long time due to excellent Impact resistance, acid and alkali resistance, corrosion resistance

• Simple installation and low maintenance cost

• Working temperature range -60°C-80°C