Armoured Rubber Hose are used for dredging sharp materials which have bigger volume, heavy specific materials like coarse sand, coral reef or weathered rock. The hoses have the ring of high abrasion resistance, inner lining of excellent abrasion resistant performance and bending resistance. It’s available in diameters up to 1300mm and in various lengths and pressure ranges. It can be equipped with rubber flanges or steel flanges on both ends of hoses. Dredge hoses are produced to the specifications of your needs.

Armored Hoses are suitable for ambient temperatures ranging from -20℃ to 60℃, and suitable for conveying mixtures of water(or seawater), silt, mud, clay and sand, ranging in specific gravity from 1.0 g/cm3 to 2.3g/cm3, , especially suitable for conveying gravel, flaky weathered rock and coral reefs.

Armored Hose are divided into armored floating hose and armored suction-discharge hose.

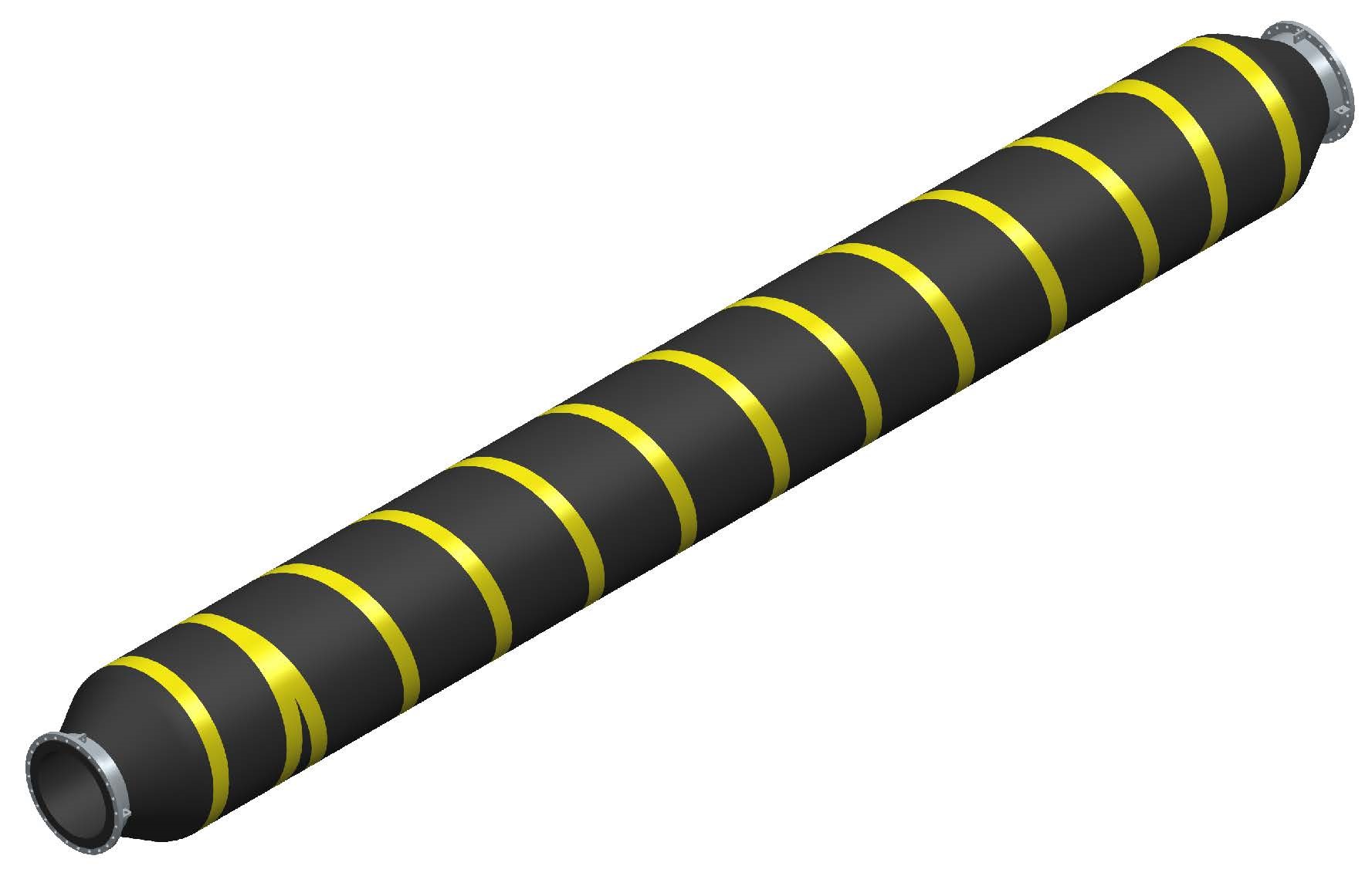

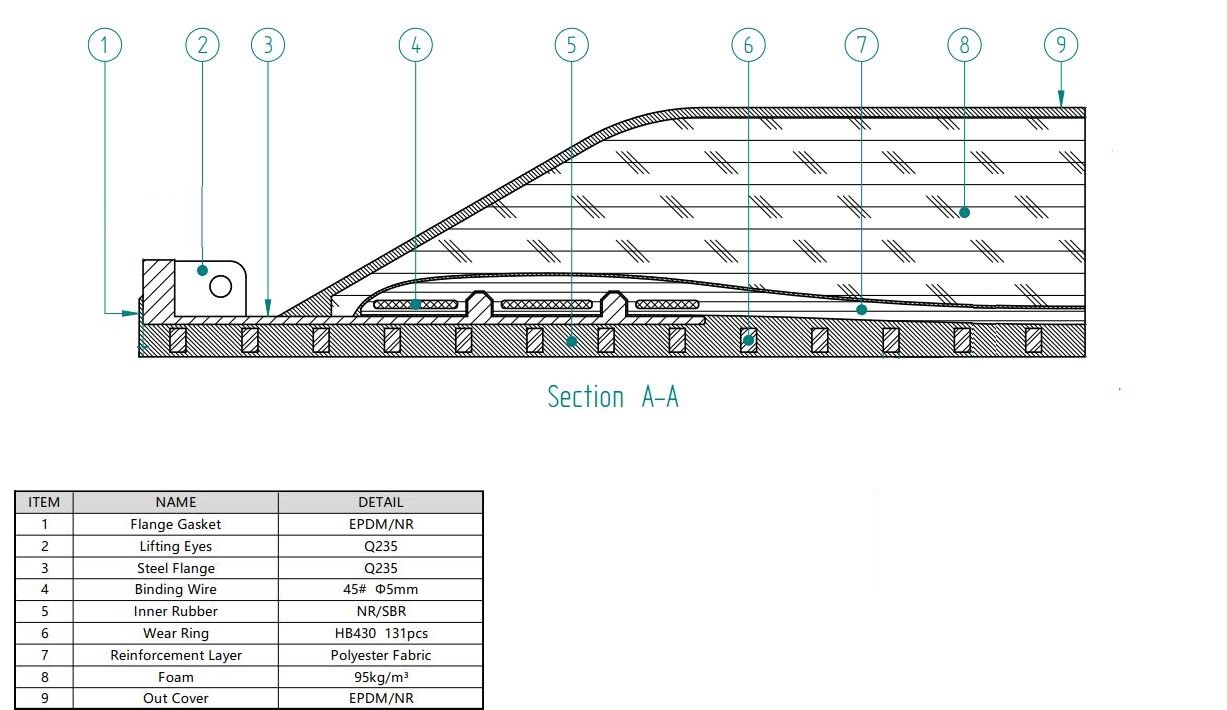

Armored Floating Hose

An Armored Floating Hose is composed of lining, wear-resistant steel rings, reinforcing piles, flotation jacket, outer cover and hose fittings at both ends.

Advantages

1. Adopting wear-resistant ring embedding technology, make the hose more adaptable to working conditions with high requirements.

2. With excellent wear resistance and impact resistance.

3. With good flexibility and bending performance.

4. With moderate stiffness.

5. With high pressure bearing capacity and wide range of pressure ratings.

6. With floating performance.

Technical Parameters

Nominal Bore Size | 500mm, 600mm, 650mm, 700mm, 750mm, 800mm, 850mm, 900mm, 1000mm, 1100mm, 1200mm, 1300mm |

Hose Length | 6m~ 11.8m (tolerance ± 2%) |

Working Pressure | 1.0 Mpa ~ 4.5 Mpa |

Buoyancy Level | SG 1.0~SG 2.5 |

Wear-resistant hardness | HB400 ~HB600 |

* Customized specifications are also available. | |

Armored Suction-Discharge Hose

An Armored Suction-Discharge Hose is composed of lining, wear-resistant steel rings, reinforcing piles, out cover and hose fittings at both ends. Usually the material of the wear-resistant steel ring is alloy steel.

Advantages

1. Adopting wear-resistant ring embedding technology.

2. With excellent wear resistance and impact resistance.

3. With good shock absorption, elasticity and sealing property.

Technical Parameters

Nominal Bore Size | 350mm, 400mm, 450mm, 500mm, 600mm, 650mm, 700mm, 750mm, 800mm, 850mm, 900mm, 1000mm, 1100mm, 1200mm |

Hose Length | 0.8m~ 2.5m (tolerance ± 2%) |

Working Pressure | 0.8 Mpa ~ 3.0 Mpa |

Wear-resistant hardness | HB400 ~HB600 |

* Customized specifications are also available. | |